Our plant

Caremag: accelerating the energy transition through rare-earth recycling.

« We’re developing the first industrial facility in Europe to produce rare-earth oxides using an environmentally responsible, high-performance process. »

Frédéric Carencotte

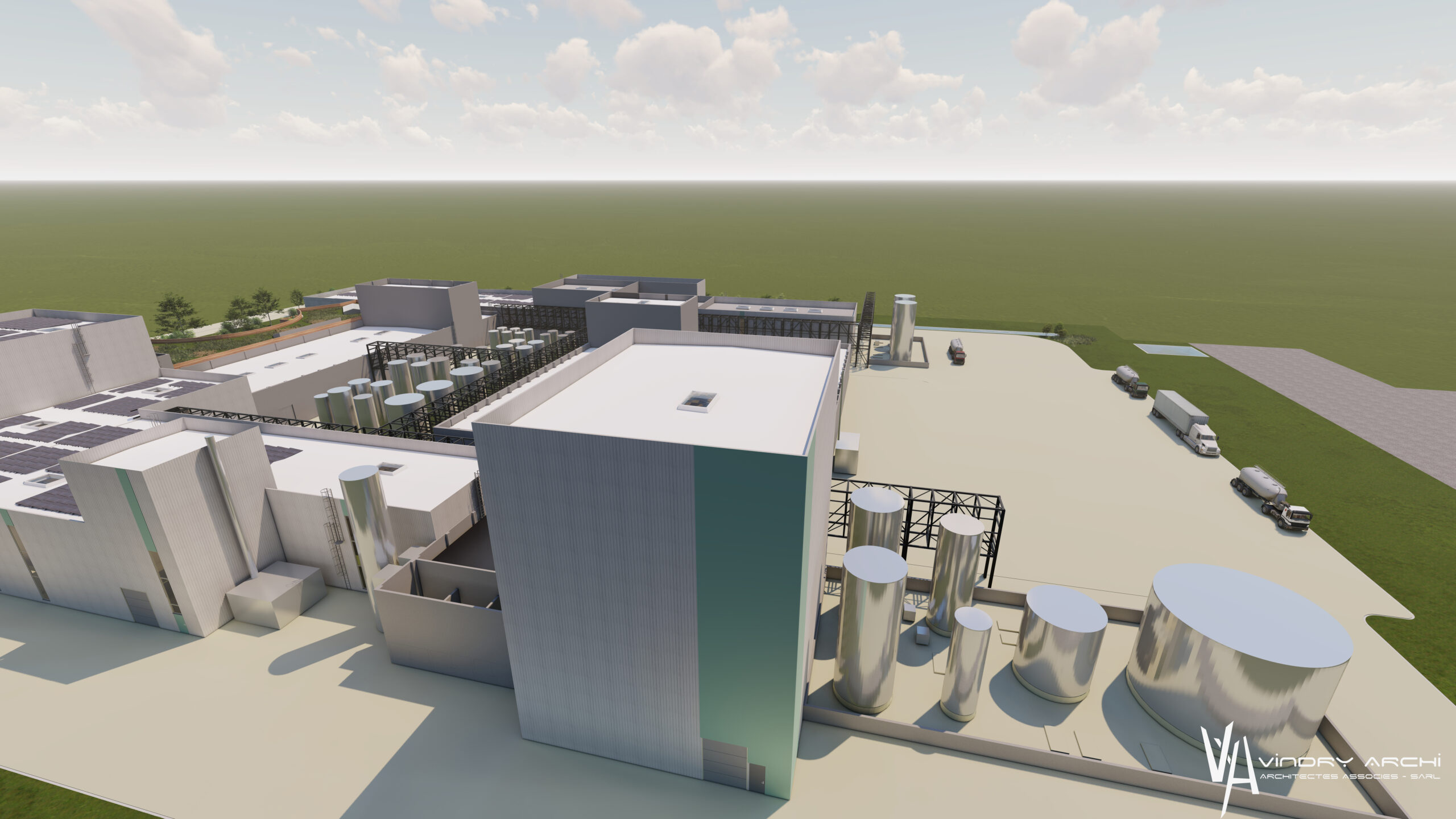

Caremag factory

The European pioneer in recycling rare earth elements from permanent magnets in end-of-life equipment.

The project

The project

The Caremag plant located in Lacq, France will produce pure rare-earth oxides from two main sources, recycled permanent magnets and mineral concentrates containing heavy rare earths. As a pioneer in long-loop recycling, the plant can process all types of magnets and produces pure rare-earth oxides, enabling complete circularity: new magnets produced from these materials retain their original quality.

This state-of-the-art facility, designed to meet the highest environmental and digital standards, incorporates groundbreaking innovations to reduce CO2 emissions, minimize water consumption, eliminate liquid effluents, recycle emitted CO2 on-site, and recover co-products. This innovative process, designed by Carester, ensures the plant will be a competitive market force.

Caremag will address Europe’s growing need for rare-earth permanent magnets, particularly in the wind energy and automotive sectors.

Starting from an initial mix of mining and recycled sources, Caremag aims to gradually transition toward a model primarily focused on recycling, with the ultimate goal of achieving carbon neutrality.

Inputs and outputs

The project

Process characteristics

Today

From design to implementation.

November 2020

Creation of the project

October 2021

Start of dismantling in Echiré, France

February 2023

Building permit obtained for the Lacq, France plant

September 2023

Operating permit obtained for Lacq plant

October 2023

Setup of dismantling activity in Vénissieux, France

December 2024

Decision to invest in Lacq plant

December 2024

Decision to invest in Lacq plant

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi nunc nunc, consectetur in pharetra id, vehicula quis dui. Aenean viverra libero ac elementum luctus. Mauris consectetur est eu nibh bibendum, sed auctor sapien suscipit. Donec mattis commodo nisl vel tincidunt. Etiam urna augue, efficitur vitae metus quis, feugiat varius risus.

September 2023

Operating permit obtained for Lacq plant

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi nunc nunc, consectetur in pharetra id, vehicula quis dui. Aenean viverra libero ac elementum luctus. Mauris consectetur est eu nibh bibendum, sed auctor sapien suscipit. Donec mattis commodo nisl vel tincidunt. Etiam urna augue, efficitur vitae metus quis, feugiat varius risus.

August 2023

Setup of dismantling activity in Vénissieux, France

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi nunc nunc, consectetur in pharetra id, vehicula quis dui. Aenean viverra libero ac elementum luctus. Mauris consectetur est eu nibh bibendum, sed auctor sapien suscipit. Donec mattis commodo nisl vel tincidunt. Etiam urna augue, efficitur vitae metus quis, feugiat varius risus.

February 2023

Building permit obtained for the Lacq, France plant

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi nunc nunc, consectetur in pharetra id, vehicula quis dui. Aenean viverra libero ac elementum luctus. Mauris consectetur est eu nibh bibendum, sed auctor sapien suscipit. Donec mattis commodo nisl vel tincidunt. Etiam urna augue, efficitur vitae metus quis, feugiat varius risus.

October 2021

Start of dismantling in Echiré, France

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi nunc nunc, consectetur in pharetra id, vehicula quis dui. Aenean viverra libero ac elementum luctus. Mauris consectetur est eu nibh bibendum, sed auctor sapien suscipit. Donec mattis commodo nisl vel tincidunt. Etiam urna augue, efficitur vitae metus quis, feugiat varius risus.

November 2020

Creation of the project

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Morbi nunc nunc, consectetur in pharetra id, vehicula quis dui. Aenean viverra libero ac elementum luctus. Mauris consectetur est eu nibh bibendum, sed auctor sapien suscipit. Donec mattis commodo nisl vel tincidunt. Etiam urna augue, efficitur vitae metus quis, feugiat varius risus.

Magnet purchasing

Caremag recycles 100% of the permanent magnets from your end-of-life equipment.

Do you have NdFeB magnets to recycle or equipment (stacks, rotors, or electric motors) containing permanent magnets? Caremag offers a turnkey solution: we purchase your magnets (without conditions or requirements), dismantle your equipment, and optimally recover all materials.

Products

Rare-earth oxides produced in France with a low environmental impact. In the future, these will be 100% recycled.