Our services

Carester’s ecosystem of experts supports and advises rare-earth sector companies through a responsible, made-to-measure approach.

Services

Carester brings its globally recognized expertise to mining companies, providing customized, high-performance solutions that minimize environmental impact. From cost assessment studies (capital and operational expenditures) to start-up support for new facilities, to the design of industrial operating units, Carester draws on its expertise and ecosystem to address the specific challenges faced by new entrants in the rare-earth sector.

Carester’s expertise also extends to established rare-earth producers, offering services to optimize their operations. A natural partner, Carester works with customers to address production process challenges and streamline the organization of their plants.

One major challenge rare-earth industry stakeholders face is managing radioactivity. While the processes for removing uranium and thorium are now well-established, the market struggles with a significant issue: the elimination of Actinium-227, a decay product of Uranium-235.

Given the high radiotoxicity of Actinium-227, its removal is not only a matter of product quality but also a critical aspect of industrial safety, both at production sites and during transport.

Carester’s Research and Development teams have spent many years developing a process to eliminate radioactivity. This unique technology, protected by multiple patents, is more cost-effective than existing methods and enables the complete removal of radioactive elements from rare-earth solutions derived from leaching operations. Importantly, it achieves this without generating waste requiring radioprotection measures.

Automation

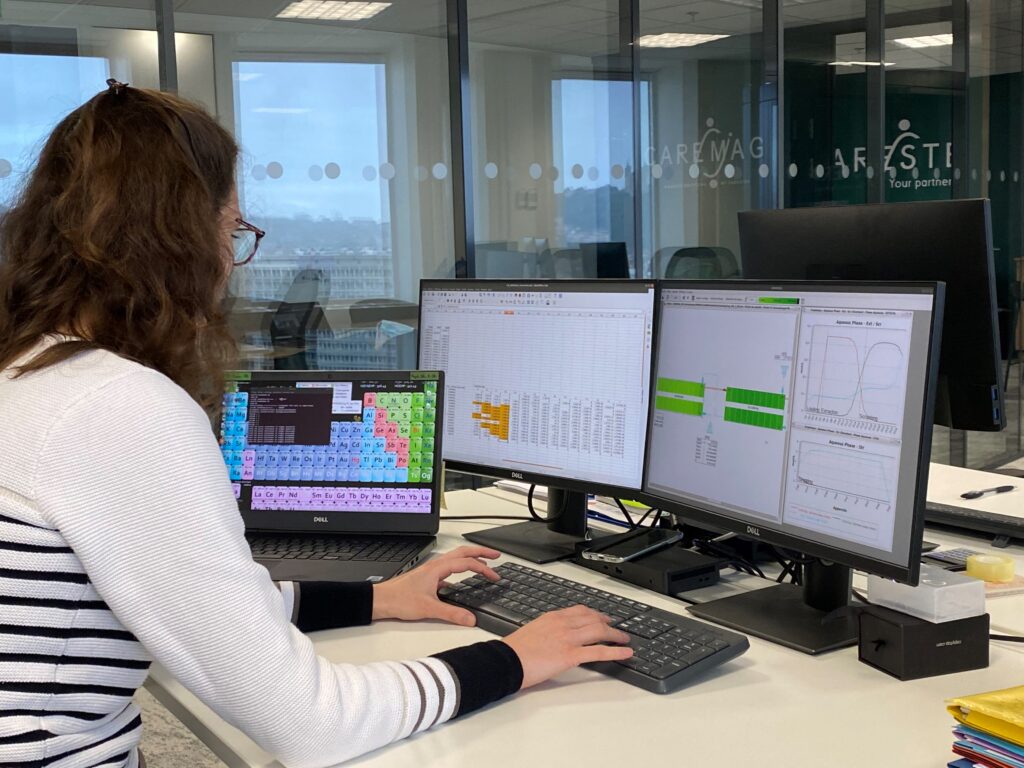

To meet the challenges of the digital transition, Carester has partnered with experts in artificial intelligence to develop a unique tool to automate operation of liquid-liquid extraction batteries.

Leveraging unmatched expertise in digital technology, a deep understanding of physicochemical mechanisms, online analysis, modeling, and field experience, Carester is engineering an innovative, revolutionary tool for rare-earth purification processes.

Currently in the development phase, this tool will be rolled out at the Caremag plant and made available to Carester’s customers, with a view to optimizing processes while minimizing their carbon footprint.

2025 - Carester